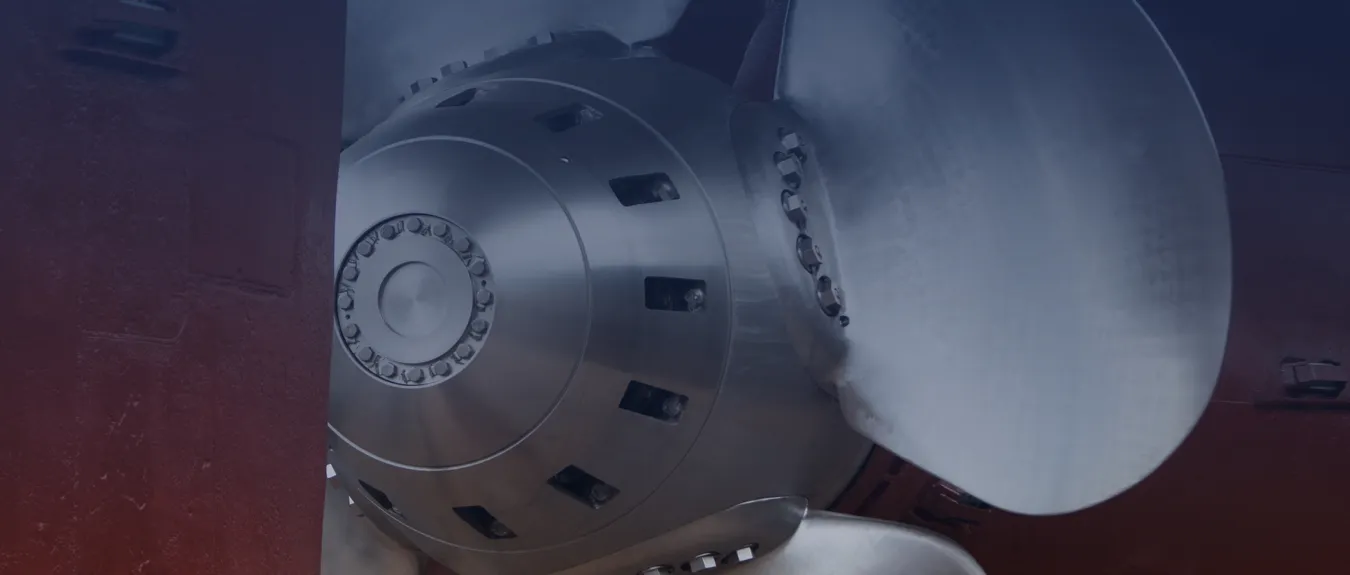

Controllable Pitch Propeller (CPP) Blades

A Controllable Pitch Propeller (CPP), also known as a variable-pitch propeller or reversible propeller, represents an advanced system that affords vessels a high degree of flexibility concerning speed, load, and draft. By adjusting the pitch of the CPP blades, vessels can optimize their performance, potentially resulting in significant enhancements in maneuverability, fuel efficiency, and overall performance. Utilizing extensive expertise, our selected partner has the capability to not only replicate but also improve upon the CPP blades of prominent brands as requested. These brands include names such as KaMeWa, Lips, Wärtsilä, MAN, Schottel, Berg Propulsion, and other manufacturers.

Controllable Pitch Propeller (CPP) Blades

Utilizing extensive expertise, our selected partner has the capability to not only replicate but also improve upon the CPP blades of prominent brands as requested.

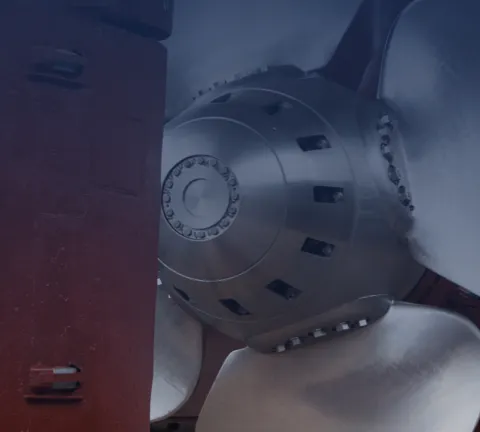

Reproduction

The reproduced Controllable Pitch Propeller (CPP) blades can be manufactured from either Cu3 aluminum bronze or CF3 or 13-4 stainless steel, in accordance with the specifications of each classification bureau.

When existing CPP blades are reproduced, reverse engineering is employed to accurately replicate the blade’s foundation. Additionally, upon request, other components of the CPP equipment, such as a hub or bolts, can also be included.

Improved Design

If the current performance of your variable-pitch propeller or reversible propeller, does not meet your expectations or if you aim to enhance the performance of your CPP, a validated Computational Fluid Dynamics (CFD) study can provide solutions.

This approach enables you to analyze and understand the hydrodynamic performance of your current vessel, potentially leading to design enhancements for the blades of your CPP to improve overall efficiency and performance.

Reproduction

The reproduced Controllable Pitch Propeller (CPP) blades can be manufactured from either Cu3 aluminum bronze or CF3 or 13-4 stainless steel, in accordance with the specifications of each classification bureau.

When existing CPP blades are reproduced, reverse engineering is employed to accurately replicate the blade’s foundation. Additionally, upon request, other components of the CPP equipment, such as a hub or bolts, can also be included.

Improved Design

If the current performance of your variable-pitch propeller or reversible propeller, does not meet your expectations or if you aim to enhance the performance of your CPP, a validated Computational Fluid Dynamics (CFD) study can provide solutions.

This approach enables you to analyze and understand the hydrodynamic performance of your current vessel, potentially leading to design enhancements for the blades of your CPP to improve overall efficiency and performance.