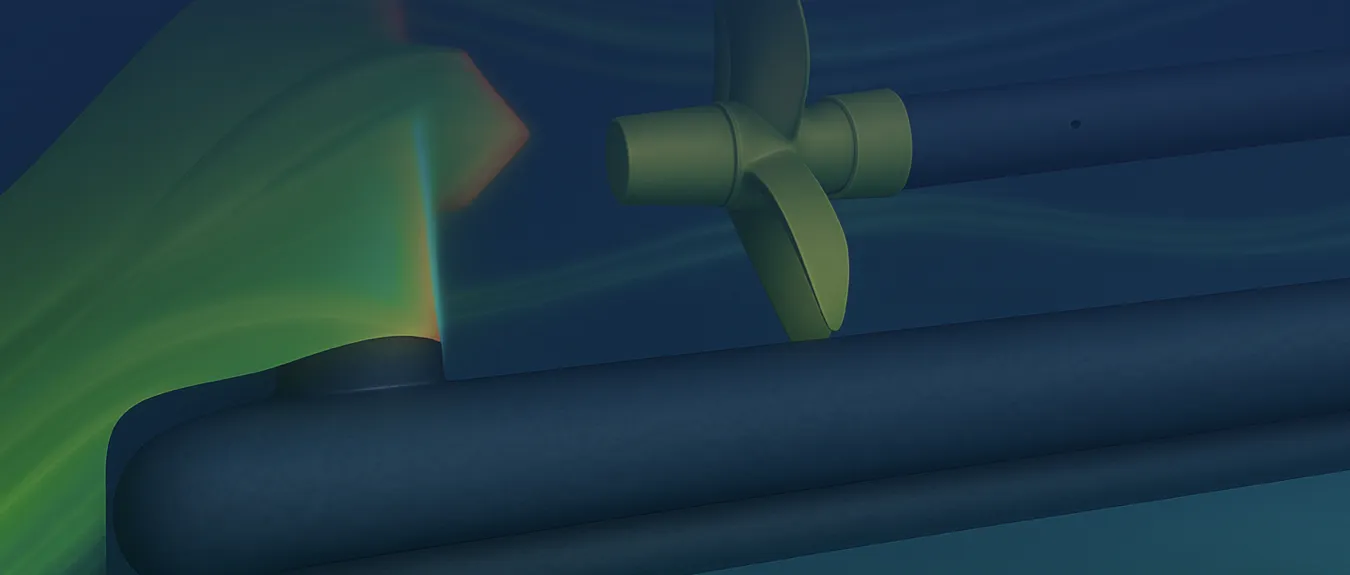

CFD Simulations for Ship Hydrodynamics

Accurately predicting both the required propulsion power and the resistance of a ship is a crucial step in developing an environmentally friendly and energy-efficient ship design. Through Computational Fluid Dynamics (CFD) simulations, the hydrodynamic performance of your ship, whether new or existing, can be precisely modeled in still water or under various sea conditions. Discover the CFD simulations services of our selected partner, specifically designed to optimize the hydrodynamics of your ship.

CFD Simulations for Ship Hydrodynamics

Discover the CFD simulations services of our selected partner, specifically designed to optimize the hydrodynamics of your ship.

Hull Form

Optimize the hull form of your existing or new ship using a validated, multidisciplinary CFD methodology. This comprehensive approach focuses not only on the bow shape but also examines the hydrodynamic performance of the stern, including propulsion components such as propellers, nozzles, and rudders. This enhanced hull form design is based on performance data obtained through monitoring or provided by you as the shipping company or shipowner.

Trim

Optimizing the trim is a crucial aspect of achieving more energy-efficient sailing. This involves adjusting the position of your ship in the water to optimize the center of buoyancy. This directly impacts water resistance and, consequently, fuel consumption. An advanced approach to this is the use of Computational Fluid Dynamics (CFD) simulations. Through this analysis, detailed insights are gained into the water flows around your ship, allowing various trim configurations to be effectively explored.

Self-Propulsion

Validated numerical self-propulsion tests can be conducted to simulate and enhance the hydrodynamics of your vessel. These CFD simulations, also known as self-propulsion tests, accurately replicate the sailing behavior of your vessel with its designed propeller. Thanks to extensive experience in CFD-optimized ship propellers and the validation of results in practice, the expected performance in operational sailing situations can be predicted with high accuracy.

Bollard Pull

With CFD-based bollard pull analyses, the maximum pulling force can be accurately calculated. This is particularly relevant for tugboats that are often utilized to assist large vessels in docking or navigating through narrow passages. In such situations, the tugboat’s maximum pulling force is crucial for executing effective maneuvers and maintaining control over the towed vessel.

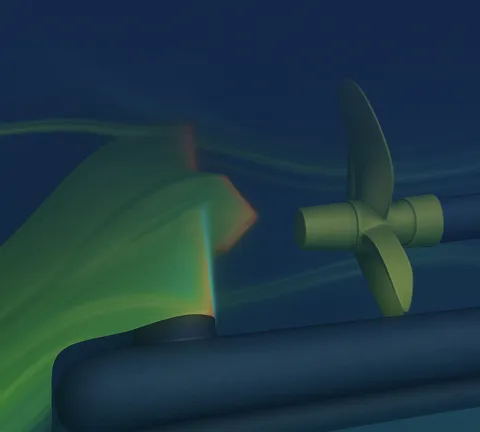

Propulsion

In addition to optimizing hull shape and trim, CFD offers the opportunity to enhance the hydrodynamic performance of individual propulsion components, such as ship propellers, nozzles, and rudders. Whether you are specifically interested in a new, optimized propeller or want to explore various rudder and/or nozzle profiles, CFD simulations enable you to determine the most optimal design tailored to your vessel and sailing profile.

Express Analysis

The International Convention for the Prevention of Pollution from Ships (MARPOL) mandates regulations to gradually reduce the carbon intensity of the global shipping fleet. Examples of these regulations include the Ship Energy Efficiency Management Plan (SEEMP), the Energy Efficiency Design Index (EEDI), the Energy Efficiency Existing Ship Index (EEXI), and the Carbon Intensity Indicator (CII).

The Express Analysis not only focuses on simulating and optimizing the hydrodynamics of your ship but also explores a range of energy-saving techniques above the waterline. This ensures compliance with current and future maritime environmental laws and regulations.

In Practice

With passion and dedication, shipowners, as well as small, medium, and large shipping companies, are supported in making their current and future ship designs more sustainable and efficient.

Hull Form

Optimize the hull form of your existing or new ship using a validated, multidisciplinary CFD methodology.

This comprehensive approach focuses not only on the bow shape but also examines the hydrodynamic performance of the stern, including propulsion components such as propellers, nozzles, and rudders.

This enhanced hull form design is based on performance data obtained through monitoring or provided by you as the shipping company or shipowner.

Trim

Optimizing the trim is a crucial aspect of achieving more energy-efficient sailing. This involves adjusting the position of your ship in the water to optimize the center of buoyancy. This directly impacts water resistance and, consequently, fuel consumption.

An advanced approach to this is the use of Computational Fluid Dynamics (CFD) simulations. Through this analysis, detailed insights are gained into the water flows around your ship, allowing various trim configurations to be effectively explored.

Self-Propulsion

Validated numerical self-propulsion tests can be conducted to simulate and enhance the hydrodynamics of your vessel. These CFD simulations, also known as self-propulsion tests, accurately replicate the sailing behavior of your vessel with its designed propeller.

Thanks to extensive experience in CFD-optimized ship propellers and the validation of results in practice, the expected performance in operational sailing situations can be predicted with high accuracy.

Bollard Pull

With CFD-based bollard pull analyses, the maximum pulling force can be accurately calculated. This is particularly relevant for tugboats that are often utilized to assist large vessels in docking or navigating through narrow passages.

In such situations, the tugboat’s maximum pulling force is crucial for executing effective maneuvers and maintaining control over the towed vessel.

Propulsion

In addition to optimizing hull shape and trim, CFD offers the opportunity to enhance the hydrodynamic performance of individual propulsion components, such as ship propellers, nozzles, and rudders.

Whether you are specifically interested in a new, optimized propeller or want to explore various rudder and/or nozzle profiles, CFD simulations enable you to determine the most optimal design tailored to your vessel and sailing profile.

Express Analysis

The International Convention for the Prevention of Pollution from Ships (MARPOL) mandates regulations to gradually reduce the carbon intensity of the global shipping fleet.

Examples of these regulations include the Ship Energy Efficiency Management Plan (SEEMP), the Energy Efficiency Design Index (EEDI), the Energy Efficiency Existing Ship Index (EEXI), and the Carbon Intensity Indicator (CII).

The Express Analysis not only focuses on simulating and optimizing the hydrodynamics of your ship but also explores a range of energy-saving techniques above the waterline. This ensures compliance with current and future maritime environmental laws and regulations.

In Practice

With passion and dedication, shipowners, as well as small, medium, and large shipping companies, are supported in making their current and future ship designs more sustainable and efficient.

Frequently Asked Questions

What is CFD, and how does it relate to the hydrodynamics of my ship?

CFD, or Computational Fluid Dynamics, is an advanced technique used to simulate and analyze the hydrodynamics of both existing and new ships. With CFD, flow and resistance are calculated, providing deep insights into potential improvements for ship design, such as optimizations to the bow, trim, stern, and appendages like propellers, nozzles and rudders.

Moreover, practically validated CFD tests are employed to precisely replicate the sailing behavior of your ship in a digital towing tank. This approach offers similar insights to physical tests on the specific ship or experiments in a model basin. As a result, it provides a detailed assessment to enhance efficiency and performance.

For which sectors in the maritime industry are these CFD simulations for optimizing ship hydrodynamics suitable?

The expertise in CFD simulations, focused on optimizing ship hydrodynamics, is applicable to various sectors in the maritime industry. This includes seagoing shipping, coastal shipping, cruise ships, fast ferries, offshore vessels, inland shipping, dredging, fishing, naval vessels, and mega yacht construction.